Lithium-ion battery transportation

Time:2019-09-25 Hits779 【Font size:F16 F14 F12】

Lithium-ion battery transportation methods include air transportation, water transportation, and land transportation. The most common air transportation and ocean transportation are discussed here.

Since lithium is a metal that is particularly prone to chemical reactions, it is easy to extend and burn. Lithium batteries are packaged and transported, such as improper handling, flammability and explosion, and accidents sometimes occur. Accidents caused by non-standard behaviors in packaging and transportation are receiving more and more attention. Many international agencies have issued a number of regulations, and various regulatory agencies have become more stringent, improving operational requirements, and constantly modifying regulations and regulations.

Major regulatory agencies and regulatory areas

Management organization

United Nations (UN) worldwide, various forms of transport

International Civil Aviation Organization (ICAO) worldwide, aircraft

Air Transport Association (IATA) Worldwide, Aircraft

International Maritime Organization (IMO) Worldwide, Shipping

US Department of Transportation (USDOT) USA, various forms of transportation

European Ground Transportation Agreement (ADR) Europe, Ground Transportation

Main regulations

IATA Lithium Battery Transport Guide 2013 [1] 54th Edition

Basic requirements for lithium battery transportation

1) Lithium battery and lithium battery pack are classified as Class 9 dangerous goods

2) All lithium batteries (groups) must pass the UN38.3 test

3) Exceptional provisions for the transportation of some Class 9 dangerous lithium batteries

4) Strict restrictions on transport samples

5) Restrictions on daily-use lithium batteries carried by passengers

6) Restrictions on the carriage of all defective batteries or damaged batteries

Corresponding classification for lithium battery transportation

Lithium battery transportation first needs to provide the corresponding UN number. The lithium battery is classified as the following UN number and is classified in the category 9 miscellaneous dangerous goods:

UN3090, Lithium metal batteries

UN3480, Lithium ion batteries

UN3091, Lithium metal batteries contained in equipment

UN3091, Lithium metal batteries packed with equipment

UN3481, Lithium ion battery contained in equipment

UN3481, Lithium ion batteries packed with equipment

Lithium battery distinction

Lithium metal battery: A disposable battery that generally functions as an anode from a lithium metal or lithium mixture.

Lithium-ion battery: Lithium-ion battery (abbreviated as Li ion Batteries) lithium compound as a positive electrode, which can make lithium ion intercalated and deintercalated carbon material instead of pure lithium as the negative electrode, and mixed electrolyte as the electrolyte liquid. It is a rechargeable battery that is commonly used in the consumer electronics industry.

The batteries produced by different lithium ion battery materials can be divided into: polymer batteries, square batteries, cylindrical batteries (usually 18650 batteries).

Lithium battery and lithium battery core

The technical definitions of the batteries and cells mentioned in the manual of the United Nations Inspection and Standards are as follows:

"Battery" Two or more cells that are connected together by a circuit and are equipped with the necessary equipment for use, such as housings, electrode terminals, markings, and protective devices.

A single-cell battery is considered a "cell" (treated on a cell core during the UN38.3 test). A "cell" consists of a single, closed electrochemical device with a positive electrode and a negative electrode with a potential difference between the two electrodes. Regardless of these rules and UN test standards and manuals, such electrochemical units are referred to as "batteries" or "single-cell batteries," which are referred to as "cells" in our rules and UN test standards and manuals. Not a battery. In a DGR, a single-cell battery should be considered as a battery core rather than a battery.

Generally, the most used lithium batteries are button batteries, etc.;

The lithium battery in notebook computers and power tools is composed of several (3~9 unequal) batteries connected in series and parallel; the power lithium battery pack consists of dozens to hundreds of batteries connected in series and parallel with protection. Line device, providing power to it;

In mobile phones, MP3 is basically a single lithium-ion battery or a single lithium polymer battery, and a protective circuit device is used to form a battery.

Lithium battery measurement standard

The new lithium battery measurement standard is: rated watt hour (Wh), if the nominal voltage (V) and nominal capacity (Ah) of the battery are known, the value of the rated watt hour can be calculated: Wh = V x Ah ampere Multiplied by the nominal voltage equals the watt-hour nominal voltage and nominal capacity, which is required to be marked on the battery.

Lithium battery transportation packaging and transportation requirements

Lithium battery transport packaging

1. These batteries must be shipped in accordance with the restrictions in the rules (package instructions applicable to DGR 4.2) without regard to exceptions [2]. They must be placed in the UN specification package as specified in the DGR Dangerous Goods Regulations in accordance with the applicable packaging instructions and the corresponding number on the package.

2. A package that meets the requirements, except for the mark marked with the appropriate transport-specific name and UN number.

Since lithium is a metal that is particularly prone to chemical reactions, it is easy to extend and burn. Lithium batteries are packaged and transported, such as improper handling, flammability and explosion, and accidents sometimes occur. Accidents caused by non-standard behaviors in packaging and transportation are receiving more and more attention. Many international agencies have issued a number of regulations, and various regulatory agencies have become more stringent, improving operational requirements, and constantly modifying regulations and regulations.

Major regulatory agencies and regulatory areas

Management organization

United Nations (UN) worldwide, various forms of transport

International Civil Aviation Organization (ICAO) worldwide, aircraft

Air Transport Association (IATA) Worldwide, Aircraft

International Maritime Organization (IMO) Worldwide, Shipping

US Department of Transportation (USDOT) USA, various forms of transportation

European Ground Transportation Agreement (ADR) Europe, Ground Transportation

Main regulations

IATA Lithium Battery Transport Guide 2013 [1] 54th Edition

Basic requirements for lithium battery transportation

1) Lithium battery and lithium battery pack are classified as Class 9 dangerous goods

2) All lithium batteries (groups) must pass the UN38.3 test

3) Exceptional provisions for the transportation of some Class 9 dangerous lithium batteries

4) Strict restrictions on transport samples

5) Restrictions on daily-use lithium batteries carried by passengers

6) Restrictions on the carriage of all defective batteries or damaged batteries

Corresponding classification for lithium battery transportation

Lithium battery transportation first needs to provide the corresponding UN number. The lithium battery is classified as the following UN number and is classified in the category 9 miscellaneous dangerous goods:

UN3090, Lithium metal batteries

UN3480, Lithium ion batteries

UN3091, Lithium metal batteries contained in equipment

UN3091, Lithium metal batteries packed with equipment

UN3481, Lithium ion battery contained in equipment

UN3481, Lithium ion batteries packed with equipment

Lithium battery distinction

Lithium metal battery: A disposable battery that generally functions as an anode from a lithium metal or lithium mixture.

Lithium-ion battery: Lithium-ion battery (abbreviated as Li ion Batteries) lithium compound as a positive electrode, which can make lithium ion intercalated and deintercalated carbon material instead of pure lithium as the negative electrode, and mixed electrolyte as the electrolyte liquid. It is a rechargeable battery that is commonly used in the consumer electronics industry.

The batteries produced by different lithium ion battery materials can be divided into: polymer batteries, square batteries, cylindrical batteries (usually 18650 batteries).

Lithium battery and lithium battery core

The technical definitions of the batteries and cells mentioned in the manual of the United Nations Inspection and Standards are as follows:

"Battery" Two or more cells that are connected together by a circuit and are equipped with the necessary equipment for use, such as housings, electrode terminals, markings, and protective devices.

A single-cell battery is considered a "cell" (treated on a cell core during the UN38.3 test). A "cell" consists of a single, closed electrochemical device with a positive electrode and a negative electrode with a potential difference between the two electrodes. Regardless of these rules and UN test standards and manuals, such electrochemical units are referred to as "batteries" or "single-cell batteries," which are referred to as "cells" in our rules and UN test standards and manuals. Not a battery. In a DGR, a single-cell battery should be considered as a battery core rather than a battery.

Generally, the most used lithium batteries are button batteries, etc.;

The lithium battery in notebook computers and power tools is composed of several (3~9 unequal) batteries connected in series and parallel; the power lithium battery pack consists of dozens to hundreds of batteries connected in series and parallel with protection. Line device, providing power to it;

In mobile phones, MP3 is basically a single lithium-ion battery or a single lithium polymer battery, and a protective circuit device is used to form a battery.

Lithium battery measurement standard

The new lithium battery measurement standard is: rated watt hour (Wh), if the nominal voltage (V) and nominal capacity (Ah) of the battery are known, the value of the rated watt hour can be calculated: Wh = V x Ah ampere Multiplied by the nominal voltage equals the watt-hour nominal voltage and nominal capacity, which is required to be marked on the battery.

Lithium battery transportation packaging and transportation requirements

Lithium battery transport packaging

1. These batteries must be shipped in accordance with the restrictions in the rules (package instructions applicable to DGR 4.2) without regard to exceptions [2]. They must be placed in the UN specification package as specified in the DGR Dangerous Goods Regulations in accordance with the applicable packaging instructions and the corresponding number on the package.

2. A package that meets the requirements, except for the mark marked with the appropriate transport-specific name and UN number.

There are also 9 types of dangerous labels that must be attached.

3. The shipper must fill out the dangerous goods declaration form; provide the corresponding dangerous package certificate;

Provide a transportation appraisal report issued by the certified third institution and display it as a standard-compliant product (including UN38.3 test, 1.2 m drop packaging test).

Lithium battery air transportation requirements

1. The battery must pass the UN 38.3 test [3] requirements, and the 1.2 m drop package test

2. The dangerous goods declaration document provided by the shipper, marked with the UN number

3. All types of dangerous goods labels must be affixed to the outer packaging, and the “All-Cargo Transportation Only” operation label is attached.

3. The shipper must fill out the dangerous goods declaration form; provide the corresponding dangerous package certificate;

Provide a transportation appraisal report issued by the certified third institution and display it as a standard-compliant product (including UN38.3 test, 1.2 m drop packaging test).

Lithium battery air transportation requirements

1. The battery must pass the UN 38.3 test [3] requirements, and the 1.2 m drop package test

2. The dangerous goods declaration document provided by the shipper, marked with the UN number

3. All types of dangerous goods labels must be affixed to the outer packaging, and the “All-Cargo Transportation Only” operation label is attached.

4. It should be designed to prevent bursting under normal conditions of transport and is equipped with effective measures to prevent external short circuits.

5. In a rugged outer packaging, the battery should be protected against short circuits and should be protected from contact with conductive materials that can cause short circuits in the same package.

6. Additional requirements for battery installation in the equipment:

a. The equipment should be secured to prevent the battery from moving within the package in such a way as to prevent the battery from accidentally starting during transport.

b. The outer packaging should be waterproof or waterproof by using a lining (such as a plastic bag) unless the structural features of the device itself are already waterproof.

7. Lithium batteries should be loaded on the pallet to avoid strong vibration during handling. The vertical and horizontal edges of the tray are protected by corners.

8. The weight of a single package is less than 35 kgs.

9. Airline operation note:

l All cargo aircraft only

l Lithium battery air transport information appears on the captain's notice

l Increased crew awareness and decision making in emergency situations may change

l Inform the first arrival personnel of the type and quantity of batteries in the cargo hold

l The US FAA requires lithium batteries to be loaded in the Class C cargo hold of the aircraft. The cargo hold must have a smoke detection system, an alarm system, and a fire suppression system.

Lithium battery marine transportation requirements

1. The battery shall pass the UN 38.3 test requirements and a 1.2 m drop package test.

2. The outer packaging must be labeled with 9 types of dangerous goods, marked with the UN number.

3. It is designed to prevent bursting under normal transportation conditions and is equipped with effective measures to prevent external short circuits.

4. In a rugged outer packaging, the battery should be protected against short circuits and should be protected from contact with conductive materials that can cause short circuits in the same package.

5. Additional requirements for battery installation in equipment:

a. The equipment should be secured to prevent movement within the package and should be packaged in such a way as to prevent accidental activation during transit.

b. The outer packaging should be waterproof or waterproof by using an inner lining (such as a plastic bag) unless the structural features of the device itself are already waterproof.

6. Lithium batteries should be loaded on the pallet to avoid strong vibration during handling. The vertical and horizontal sides of the tray are protected by corners.

7. Lithium battery loading containers must be reinforced. The reinforcement method and strength should meet the requirements of the importing country (eg: American Railway Association <ARR>, American Dangerous Goods Association, North American Explosives Administration <BOE>, Federal Motors Transportation Security Administration, US Coast Guard, US Transportation

5. In a rugged outer packaging, the battery should be protected against short circuits and should be protected from contact with conductive materials that can cause short circuits in the same package.

6. Additional requirements for battery installation in the equipment:

a. The equipment should be secured to prevent the battery from moving within the package in such a way as to prevent the battery from accidentally starting during transport.

b. The outer packaging should be waterproof or waterproof by using a lining (such as a plastic bag) unless the structural features of the device itself are already waterproof.

7. Lithium batteries should be loaded on the pallet to avoid strong vibration during handling. The vertical and horizontal edges of the tray are protected by corners.

8. The weight of a single package is less than 35 kgs.

9. Airline operation note:

l All cargo aircraft only

l Lithium battery air transport information appears on the captain's notice

l Increased crew awareness and decision making in emergency situations may change

l Inform the first arrival personnel of the type and quantity of batteries in the cargo hold

l The US FAA requires lithium batteries to be loaded in the Class C cargo hold of the aircraft. The cargo hold must have a smoke detection system, an alarm system, and a fire suppression system.

Lithium battery marine transportation requirements

1. The battery shall pass the UN 38.3 test requirements and a 1.2 m drop package test.

2. The outer packaging must be labeled with 9 types of dangerous goods, marked with the UN number.

3. It is designed to prevent bursting under normal transportation conditions and is equipped with effective measures to prevent external short circuits.

4. In a rugged outer packaging, the battery should be protected against short circuits and should be protected from contact with conductive materials that can cause short circuits in the same package.

5. Additional requirements for battery installation in equipment:

a. The equipment should be secured to prevent movement within the package and should be packaged in such a way as to prevent accidental activation during transit.

b. The outer packaging should be waterproof or waterproof by using an inner lining (such as a plastic bag) unless the structural features of the device itself are already waterproof.

6. Lithium batteries should be loaded on the pallet to avoid strong vibration during handling. The vertical and horizontal sides of the tray are protected by corners.

7. Lithium battery loading containers must be reinforced. The reinforcement method and strength should meet the requirements of the importing country (eg: American Railway Association <ARR>, American Dangerous Goods Association, North American Explosives Administration <BOE>, Federal Motors Transportation Security Administration, US Coast Guard, US Transportation

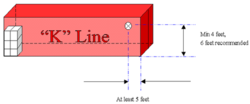

Type 9 dangerous goods container American reinforcement method

Type 9 dangerous goods container American reinforcement methodThe Ministry and the "Dangerous Goods Transportation Regulations at Sea" have relevant provisions. If the consignor neglects to reinforce or improperly rectify, the port will be detained at the port of destination, and the operation fee, storage fee, transfer fee, and reinforcement of the terminal will occur. The same amount of fees.

8. Export to North America requires the labeling of 9 dangerous goods labels at the specified locations around the container.

Freight operation process

Lithium battery air transport process

Previous: Telephone consultation > Providing solutions > Refining requirements > Document providing > Document review > Freight rate confirmation > Acceptance of commission > Booking class > Feedback information

Mid-term: Cargo warehousing > Weighing > Flight position confirmation > Dangerous goods declaration > Airport security > Delivery of goods > Goods in dangerous goods warehouse > Confirmation of bill of lading > Sending information, such as AMS, ISF... > Board loading > Flight departure

Late: Issuance of Bill of Lading > Overseas Forecast > Destination Port Forecast > Import Customs Clearance > Scheduled DG Vehicle > Delivery Receipt Warehouse > Customer Signing, Customs Return and Return

Lithium battery shipping process (full case)

Previous: Telephone consultation > Providing solutions > Refining requirements > Document providing > Document review > Freight rate confirmation > Acceptance of commission > Application for dangerous goods class > Feedback information

Mid-term: Cargo entry > Yard picking > Cargo packing > Site reinforcement > Paste hazard > Photo confirmation > Dangerous goods declaration > Container entry > B/L confirmation > Send information, such as AMS, ISF... > Enquiry of port opening plan > Container Entry > Customs Declaration

In case of inspection: Inspection and Inspection Plan > Port Shutdown Plan > Container Disshipment to Dangerous Warehouse > Personal escort inspection > Re-reinforcement > Photographed file > Second entry > Check out port information

Late: Issuance of Bill of Lading > Sending Overseas Forecasts > Destination Port Forecast > Import Clearance > Booking DG Vehicles > Delivery Receipt Warehouse > Customer Signing, Customs Return and Return

Exceptional license for lithium battery transport

a. Some indicators of lithium batteries can be transported in accordance with the exceptions of non-dangerous goods, but must meet specific performance indicators and packaging requirements, and must also be posted on the lithium battery warning label as shown in Figure 7, and no longer label 9 dangerous goods.

According to the ITAT standard, lithium batteries transported under these conditions must meet the corresponding performance specifications, packaging requirements, and packaging label requirements.

This portion of small lithium metal and lithium-ion batteries is not required to comply with all DGR provisions, ie for lithium-ion batteries in the 54th edition of IATA DGR, the second part of Packing Instructions 965, 966 and 967 (ie: 965 II, Requirements set forth in 966 II, 967 II); for lithium metal batteries, meet the requirements of Part II of Packing Instructions 968, 969 and 970 (ie: 968 II, 969 II, 970 II).

b. Differences between PI: 965, PI 968 and PI: 965 II, 968 II

In 2013, ITAT began to use the new regulations and packaging requirements, including PI: 965 Section II (965 II), PI: 968 Section II (968 II) was modified on the original PI 965, PI 968, and Differentiate the original PI: 965, PI 968 regulations.

c. Documentation requirements:

It is required to provide the "Cargo Transportation Conditions Appraisal Letter" of the third-party appraisal agency in the current year and the conclusion is as follows: It can be transported as ordinary cargo.

Provide documents such as packaging certificate and entrusted statement. At the same time, the operation of the lithium battery is still required to be marked on the air waybill to remind the crew to prevent it.

d. Common exception range products:

Most transported (separate) lithium-ion batteries meet the requirements of the UN3480 category for lithium-ion batteries that can be used for unrestricted air transport, the main products used and the corresponding requirements.

Rated energy Single piece packaging limitation factor Application product Operational requirements

|

|

Outer packaging label

|

|

|||

|

Less than 2.7Wh |

Weight limit, not limited to |

Weight less than 2.5kg |

Mp3、 Bluetooth headset |

1. Pass the UN38.3 test and the 1.2 meter drop test

2, the outer packaging is labeled with lithium battery operation label |

|

|

大于2.7Wh,

小于100Wh

|

Weight limit1~2 lithium batteries |

|

Cell phone, DV, notebook, power tool, digital camera |

Lithium battery transportation identification report and content

The contents of the "Goods Conditions for the Carriage of Goods" are reported by the UN38.3 test report and the 1.2-meter drop package test report.

UN38.3 test content

(for a single battery)

UN38.3 is Section 38.3 of the Lithium Battery Test in the Manual of Tests and Criteria prepared by the United Nations Committee of Experts on the Transport of Dangerous Goods, test content:

T.1 height test

Store at a low pressure of 20 ≤ 1 kPa and a temperature of 20 ± 5 ° C for at least 6 hours.

T.2 temperature test

Repeat high and low temperature tests at 75±2°C and -40±2°C, storage time ≥6h at extreme temperature; high and low temperature conversion time ≤30min, repeat 10 times; then store at room temperature (20±5°C) 24h, the total test time is at least one week.

T.3 vibration test

The frequency is swung between 7 Hz and 200 Hz in 15 min and back to the logarithmic sweep of 7 Hz. This vibration process must be repeated 12 times for each of the three mutually perpendicular battery mounting orientations, for a total of 3 hour. One of the vibration directions must be perpendicular to the end face.

T.4 impact test

It must withstand a half-sine wave shock with a maximum acceleration of 150 gn and a pulse duration of 6 ms. Each cell was subjected to three impacts in the positive direction of three mutually perpendicular battery mounting orientations, followed by three impacts in the opposite direction, for a total of 18 impacts. Large batteries and large battery packs are subject to a half-sine wave shock with a maximum acceleration of 50 gn and a pulse duration of 11 ms. Each cell or battery pack was subjected to three impacts in the positive direction of three mutually perpendicular battery mounting orientations, followed by three impacts in the reverse direction, for a total of 18 impacts.

T1-T4 determination conditions: weight loss is within the allowable range, no leakage, no air leakage, no disintegration, no cracking and no combustion, and the open circuit voltage of each test battery or battery pack after the test is not less than that. 90% of the voltage before the test. The battery and battery pack meet this requirement. The voltage requirements do not apply to test batteries and battery packs in a fully discharged state.

T.5 external short circuit test

Short circuit at 55±2°C and external resistance <0.1Ω, the short circuit time continues until the battery temperature returns

1 h after 55 ± 2 °C. The battery or battery pack must be observed for another 6 hours before the test is completed.

T5 Judgment Condition: The battery or battery pack meets this requirement if the case temperature does not exceed 170 ° C and there is no disintegration, no cracking, and no combustion within 6 hours after the test.

T.6: Crash test

The weight of 9.1 Kg fell from a height of 61 ± 62.5 px on a battery with a 15.8 mm round bar, and the surface temperature of the battery was examined for 6 hours.

T6 determination conditions: no disintegration / no damage / no combustion within 6 hours, battery surface temperature <170 ° C

T.7: Overcharge test

The charging current is twice the maximum charging current recommended by the manufacturer. The minimum voltage tested is as follows:

(a) When the manufacturer's recommended charging voltage is not greater than 18V, the minimum voltage tested shall be the lesser of the battery's maximum charging voltage or 22V.

(b) When the manufacturer's recommended charging voltage is greater than 18V, the minimum voltage tested shall be 1.2 times the maximum charging voltage of the battery pack.

The test should be carried out at ambient temperature. The test time should be 24 hours.

T7 determination conditions: observation for 7 days, no disintegration, no burning

T.8: Test forced discharge:

The battery is connected to a 12V DC power supply for forced discharge with maximum discharge current.

1.2 meter drop test

1.2m drop test (after packaging) packaged lithium battery dropped from 1.2m (the lowest point of the battery) to 18-20mm thick hardwood board at 20±5°C (the board is spread on the concrete floor) from X , Y, Z are positive and negative six directions, and each direction falls once. (fall 6 faces, 3 sides, 1 corner), Judging criteria:

(a). The package is not damaged;

(b). The battery and battery core are free from damage and leakage;

(c). There is no touch between the battery and the battery;

MSDS report and content

MSDS, the Material Safety Data Sheet, can also be translated as a chemical safety data sheet or a chemical safety data sheet. It is used by chemical manufacturers and importers to clarify the physical and chemical properties of chemicals (such as pH, flash point, flammability, reactivity, etc.) and the hazards to users' health (such as carcinogenicity, teratogenicity, etc.). One document.

In European countries, the Material Safety Technology / Data Sheet MSDS is also known as the Safety Data Sheet (DSS). The International Organization for Standardization (ISO) uses SDS terminology, while the United States, Canada, Australia, and many Asian countries use MSDS terminology.

MSDS is a comprehensive legal document on the chemical characteristics provided by chemical production or sales companies to customers as required by law. It provides 16 physical and chemical parameters, blasting performance, health hazards, safe use and storage, leakage disposal, first aid measures and related laws and regulations. The MSDS can be prepared by the manufacturer in accordance with the relevant rules, or can be commissioned by a professional organization.

The basic 16 categories are classified as follows:

First item: chemical name and manufacturer information

The second item: chemical composition information

Item 3: Hazard Information

Item 4: First Aid Measures

Item 5: Fire Fighting Measures

Item 6: Leakage emergency treatment

Item 7: Operation and storage

Item 8: Exposure controls and personal protective measures

Item IX: Physical and chemical properties

Item 10: Stability and reactivity

Eleventh: Toxicological information

Item 12: Ecological Information

Item 13: Disposal

Item 14: Transportation Information

Item 15: Regulatory information

Item 16: Other information

Third-party accreditation body

The qualified third-party appraisal institution confirmed by the Civil Aviation Administration of China and the airline in East China is the Testing Center of Shanghai Chemical Industry Research Institute.

The Southwestern Region has obtained a qualified third-party accreditation body accredited by the Civil Aviation Administration of China and the airline as the Dangerous Goods Aviation Safety Transportation Appraisal Center of the Second Research Institute of the Civil Aviation Administration of China.

The main risk of lithium battery transportation

a. For customers - risk of lost orders

The delivery time of R&D test samples is tight, but the UN38.3 report required for air transport is extremely long (about one month), which often delays delivery, loses customer trust, loses orders, and wastes a lot of money.

b. Risks for packaging - packaging and reinforcement factors

If the packaging is negligent or not professionally reinforced, it will be deducted from the destination port and a high fine, which will affect the delivery and will be easily complained and claimed. If there is an accident, it will face serious legal and economic losses. .

c. For the operation - the risk caused by the inspection

Lithium battery air transport 100% security inspection, the original packaging will be destroyed, if not treated or improperly handled, the packaging will be scattered in the middle, the lithium battery will be damaged;

Once the sea is inspected by the customs, it needs to be moved to the dangerous goods warehouse. The distance is long. If the control is weak, the reinforcement recovery is ignored, and the original shipping schedule cannot be met. The delivery will be delayed (about 2 weeks delay).

0755-23210254

0755-23210254